How Pulp Molding Machine Manufacturers Are Driving Green Innovation

Table of contents:

Innovations in Mold Technology for Faster, Greener Production

Energy-Efficient Features in Modern Pulp Molding Machines

Environmental Benefits of Switching to Molded Pulp Lines

Innovations in Mold Technology for Faster, Greener Production

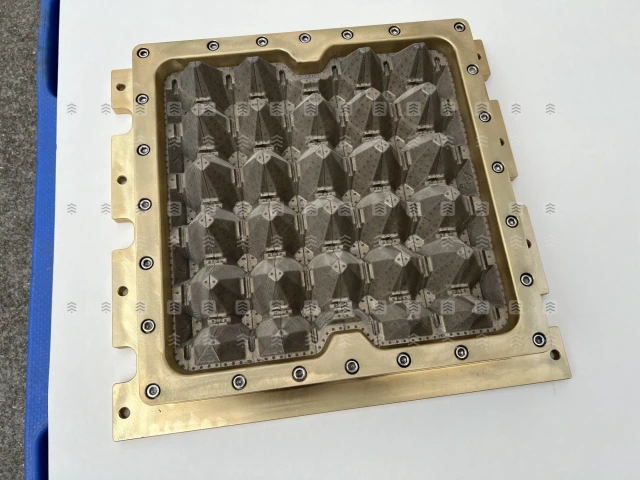

Manufacturers of pulp molding machines are leveraging cutting-edge innovations in mold technology to optimize production processes while reducing environmental impact. Precision aluminum molds are now standard in the industry, offering durability and exceptional efficiency. Take, for example, Dwellpac’s Eco Egg Tray Mold. Crafted from robust aluminum, it ensures the production of high-quality molded fiber egg cartons while maintaining consistency across large volumes. The attention to detail in these molds guarantees uniformity and eliminates quality discrepancies. What’s more, customizable designs allow producers to meet specific industry demands, from sustainable egg packaging to custom eco-friendly packaging solutions for various applications. These molds not only enhance production efficiency but also support sustainable practices by enabling the creation of products like biodegradable trays.

Energy-Efficient Features in Modern Pulp Molding Machines

Energy efficiency is a crucial focus for pulp molding machine manufacturers aiming to reduce the carbon footprint associated with industrial production. Modern machines are equipped with features that consume less energy while maintaining high output. Innovations such as optimized drying systems and energy-recycling mechanisms have drastically reduced the amount of water and electricity required during the molding process. For example, machines designed with integrated heat recovery systems use the energy generated during production to fuel subsequent stages, enhancing overall efficiency. These advancements make producing custom molded pulp packaging more sustainable, even at large scales.Another critical aspect is the automation of these machines, which minimizes human intervention and errors while speeding up production times. Automation not only saves labor costs but also ensures that every cycle runs at optimal efficiency. Such advancements allow businesses to produce eco-friendly food packaging without compromising on speed or quality.

Environmental Benefits of Switching to Molded Pulp Lines

The environmental benefits of switching to molded pulp packaging lines are substantial, making them an increasingly attractive alternative for businesses. Traditional packaging materials like plastic are notorious for their long decomposition times and harmful environmental effects. On the other hand, molded pulp packaging, such as molded fiber egg cartons or custom molded pulp packaging, is biodegradable, compostable, and made from renewable raw materials like recycled paper or agricultural fibers. By switching to these sustainable alternatives, manufacturers can significantly reduce reliance on single-use plastics and contribute to the circular economy.Companies like Dwellpac are making this transition smoother by providing tailor-made solutions for businesses with specific needs, whether it’s producing sustainable egg packaging or innovative designs for eco friendly food packaging. Beyond production, the lightweight nature of molded pulp packaging also reduces transportation-related emissions, creating an additional layer of environmental benefit. This aligns with global sustainability goals while enhancing a company’s credibility and appeal to eco-conscious consumers.For businesses looking to implement green practices, the investment in molded pulp lines is not just about compliance with regulations. It also presents a competitive advantage, as the demand for environmentally friendly products continues to grow across multiple sectors, including agriculture, food services, and retail. By adopting these solutions, businesses position themselves as leaders in sustainability, which is becoming increasingly essential in today’s competitive market landscape.

By adopting sustainable practices and leveraging eco-friendly technologies such as advanced pulp molding, businesses can play a pivotal role in shaping a healthier future for our planet. The commitment to innovation and environmental stewardship not only benefits the earth but also fosters long-term success and resilience. Together, we can create a world where economic growth and sustainability go hand in hand.

Comments

Post a Comment