Flexible Conveyor Systems: A Comprehensive Guide

Table of contents:

Understanding the Components of Flexible Conveyor Systems

How Flexible Conveyor Belts Adapt to Various Industries

The Importance of Material Selection in Flexible Conveyor Systems

Maintenance Tips for Long-Lasting Flexible Conveyor Belts

Understanding the Components of Flexible Conveyor Systems

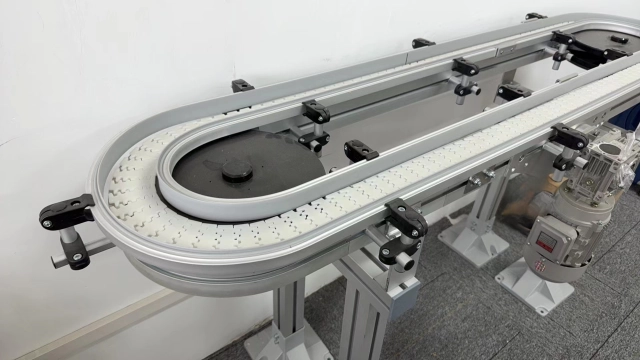

Flexible conveyor systems are composed of several key components that contribute to their functionality and efficiency. These include the conveyor belt, frame, motor, and control system. The conveyor belt is typically made from durable materials such as POM, aluminum, and steel, which are resistant to wear, acids, and alkalis. This makes them suitable for food-grade applications and other demanding environments. The frame provides structural support and is designed for easy assembly and maintenance. Motors and control systems ensure smooth operation and can be customized to meet specific requirements. As a conveyor system manufacturer, Juxin Automation emphasizes the importance of quality components to ensure long-lasting performance and reliability.

How Flexible Conveyor Belts Adapt to Various Industries

Flexible conveyor belts are designed to adapt to the needs of various industries, ranging from food processing to automotive manufacturing. Their ability to handle different types of products with ease makes them an invaluable asset for conveyor manufacturers. The customizable nature of these systems allows them to be tailored to specific industry requirements, whether it's handling delicate food items or heavy automotive parts. Their high mechanical strength and excellent product handling capabilities ensure efficient and safe transportation of goods. As a result, businesses can enhance their productivity and streamline their operations by investing in flexible conveyor systems from reputable conveyor manufacturers.

The Importance of Material Selection in Flexible Conveyor Systems

Material selection plays a crucial role in the performance and longevity of flexible conveyor systems. The choice of materials affects the system's resistance to wear, corrosion, and environmental factors. For instance, materials like POM, aluminum, and steel are favored for their durability and resistance to acids and alkalis. These properties make them ideal for conveyor systems used in food-grade applications and other challenging environments. As a conveyor system manufacturer, Juxin Automation recognizes the significance of selecting the right materials to ensure optimal performance and customer satisfaction. By choosing high-quality materials, businesses can reduce maintenance costs and extend the lifespan of their conveyor systems.

Maintenance Tips for Long-Lasting Flexible Conveyor Belts

Proper maintenance is essential to ensure the longevity and efficiency of flexible conveyor belts. Regular inspections and timely repairs can prevent costly downtime and extend the lifespan of the system. Conveyor manufacturers recommend routine checks of the belt tension, motor function, and control systems to identify potential issues early on. Cleaning the conveyor components and lubricating moving parts are also crucial for maintaining smooth operation. As a conveyor system manufacturer, Juxin Automation provides comprehensive maintenance guidelines to help businesses maximize the performance of their systems. By adhering to these recommendations, companies can ensure their conveyor systems remain in optimal condition for years to come.

Flexible conveyor systems offer a versatile and efficient solution for various industries. With their customizable features and high-quality components, these systems can be tailored to meet specific operational needs. As a leading conveyor system manufacturer, Juxin Automation provides reliable and durable solutions that enhance productivity and streamline processes. By understanding the components, adaptability, material selection, and maintenance of flexible conveyor systems, businesses can make informed decisions and invest in systems that deliver long-term benefits.

Comments

Post a Comment