Understanding the Capabilities of Tube Filling and Sealing Machines

Table of contents:

Exploring the Versatility of Automatic Tube Filling Machines

Selecting a Tube Filling Machine Supplier for Specialized Applications

The Importance of Customization in Tube Filling Machine Manufacturing

Future Trends in Tube Filling and Sealing Machine Technology

Exploring the Versatility of Automatic Tube Filling Machines

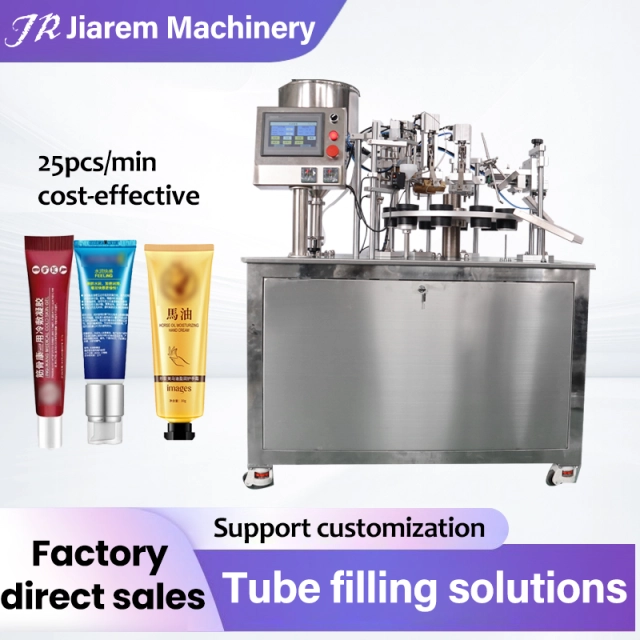

Automatic tube filling machines are designed to accommodate a wide range of tube sizes and product types, making them indispensable in diverse sectors. These machines can fill plastic and aluminum-plastic tubes with precision, supporting tube diameters from 13mm to 50mm and heights from 80mm to 200mm. The filling range varies from 5ml to 300ml, allowing manufacturers to cater to different packaging requirements. The speed of operation, typically between 10 to 30 units per minute, ensures high efficiency and productivity. A tube filling machine manufacturer often incorporates features that prevent material leakage and facilitate easy disassembly and cleaning, crucial for maintaining hygiene standards. The automatic benchmarking and customizable production dates further enhance the versatility of these machines, making them a valuable asset in any production line.

Selecting a Tube Filling Machine Supplier for Specialized Applications

Choosing the right tube filling machine supplier is essential for businesses aiming to optimize their production processes. A reliable supplier offers not only high-quality machines but also customization options to meet specific application needs. Guangzhou Jiren Automation Equipment Co., LTD, for instance, provides semi-automatic machines that are tailored for industries such as cosmetics and pharmaceuticals. Their expertise in the field ensures that clients receive machines with features like internal and external heating for superior sealing and automated tail clamping and cutting processes. A reputable supplier also guarantees rapid delivery and excellent after-sales support, including maintenance and door-to-door service. This comprehensive approach helps businesses achieve seamless integration of tube filling machines into their existing systems, enhancing overall efficiency.

The Importance of Customization in Tube Filling Machine Manufacturing

Customization is a key factor in tube filling machine manufacturing, as it allows businesses to tailor machines to their specific production requirements. A tube filling machine manufacturer with extensive experience can offer a variety of customization options, ensuring that each machine is perfectly aligned with the client's needs. From adjusting the filling range to modifying the sealing mechanisms, customization enhances the machine's ability to handle different products and packaging styles. The option to customize production dates and integrate advanced features like automatic benchmarking further adds value. Manufacturers like Guangzhou Jiren Automation Equipment Co., LTD emphasize the importance of customization in delivering machines that not only meet but exceed client expectations, ultimately driving business success.

Future Trends in Tube Filling and Sealing Machine Technology

As technology continues to advance, tube filling and sealing machines are set to become even more sophisticated and efficient. Future trends indicate a shift towards fully automated systems that minimize human intervention, enhancing speed and accuracy. Innovations in material handling, such as improved sealing techniques and more precise cutting mechanisms, are expected to emerge. A Tube filling and sealing machine supplier will likely focus on incorporating smart technology, enabling real-time monitoring and adjustments to optimize performance. Additionally, environmentally friendly solutions, such as energy-efficient designs and recyclable materials, will become more prevalent. These advancements promise to revolutionize the industry, making tube filling machines more versatile and adaptable to changing market demands.

In summary, tube filling and sealing machines are vital components in modern manufacturing processes, offering efficiency and precision across various industries. Selecting the right tube filling machine supplier ensures access to high-quality, customizable solutions that meet specific production needs. As technology evolves, these machines will continue to adapt, incorporating advanced features that enhance performance and sustainability. By understanding the capabilities and future trends of tube filling machines, businesses can make informed decisions that drive success and growth in their respective fields.

Comments

Post a Comment