Designing for Reliability with Golden Finger PCB Solutions

Table of contents:

The Impact of PCB Gold Fingers on Product Longevity

How Multilayer PCB Technology Improves Signal Integrity

Enhancing Connector Durability with Advanced Gold Finger PCBs

Double Layer PCB Strategies for Minimizing Electronic Failures

The Impact of PCB Gold Fingers on Product Longevity

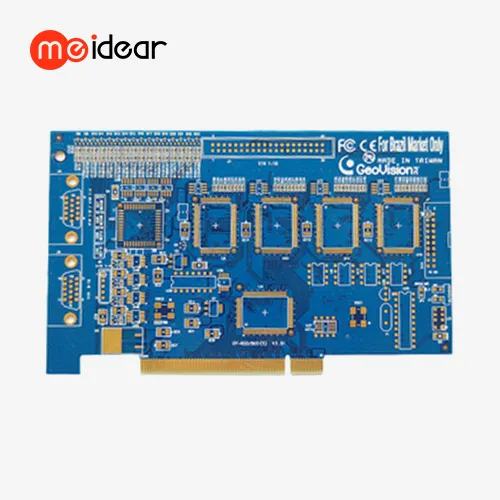

Gold fingers play a pivotal role in extending the lifespan of electronic devices. These specialized contact points, typically found on the edge of a PCB, are designed to withstand frequent insertion and removal cycles without degrading. The gold plating protects against corrosion and oxidation, ensuring consistent electrical conductivity over time. This durability is particularly crucial in applications where boards are frequently swapped or upgraded, such as in server racks or modular systems. Multilayer PCB manufacturers recognize the value of gold fingers in creating robust, long-lasting products that meet the demands of modern electronics. By incorporating gold fingers into their designs, PCB assembly service providers can significantly enhance the reliability and longevity of their clients' products, reducing the need for frequent replacements and maintenance.

How Multilayer PCB Technology Improves Signal Integrity

Multilayer PCB technology has revolutionized the way complex circuits are designed and implemented. By stacking multiple layers of conductive and insulating materials, multilayer PCB manufacturers can create boards that offer superior signal integrity and reduced electromagnetic interference. This layered approach allows for more efficient routing of signals, power, and ground planes, resulting in cleaner signal transmission and reduced crosstalk between components. The pcb assembly solution incorporating multilayer technology enables designers to create more compact and powerful devices without compromising on performance. As signal speeds continue to increase in modern electronics, the role of multilayer PCBs in maintaining signal integrity becomes even more critical, making them an essential component in high-speed digital designs.

Enhancing Connector Durability with Advanced Gold Finger PCBs

The durability of connectors is a critical factor in the overall reliability of electronic systems. Advanced Gold Finger PCBs address this challenge by providing a wear-resistant surface that can withstand thousands of mating cycles. The gold plating on these fingers is typically thicker and harder than standard surface finishes, offering superior protection against abrasion and environmental factors. PCB assembly service providers leverage this technology to create robust interconnects for applications ranging from consumer electronics to industrial equipment. The enhanced durability of Gold Finger PCBs not only extends the life of the product but also ensures consistent performance throughout its operational lifespan, making them an ideal choice for mission-critical systems where reliability is paramount.

Double Layer PCB Strategies for Minimizing Electronic Failures

Double layer PCBs offer a balanced approach to circuit design, providing improved functionality over single-layer boards while maintaining cost-effectiveness. These boards are particularly effective in minimizing electronic failures through strategic layout and component placement. By utilizing both sides of the board, designers can optimize signal paths, reduce trace lengths, and improve overall circuit performance. The pcb assembly solution for double layer boards often incorporates techniques such as ground planes and power distribution networks to enhance signal integrity and reduce noise. Multilayer PCB manufacturers and PCB assembly service providers work closely with designers to implement these strategies, ensuring that double layer PCBs meet the reliability standards required for modern electronic devices.

The adoption of Golden Finger PCB technology, along with advanced multilayer and double layer designs, marks a significant step forward in the quest for more reliable and efficient electronic systems. These innovations address critical challenges in signal integrity, connector durability, and overall product longevity. As the electronics industry continues to push the boundaries of performance and miniaturization, the role of specialized PCB solutions becomes increasingly important. Manufacturers and service providers in the PCB assembly sector are at the forefront of implementing these technologies, delivering robust and high-performance solutions to meet the evolving needs of various industries. By leveraging these advanced PCB technologies, companies can create products that not only meet current demands but are also prepared for the challenges of future electronic innovations.

Comments

Post a Comment